CNC Machinist - 2nd Shift

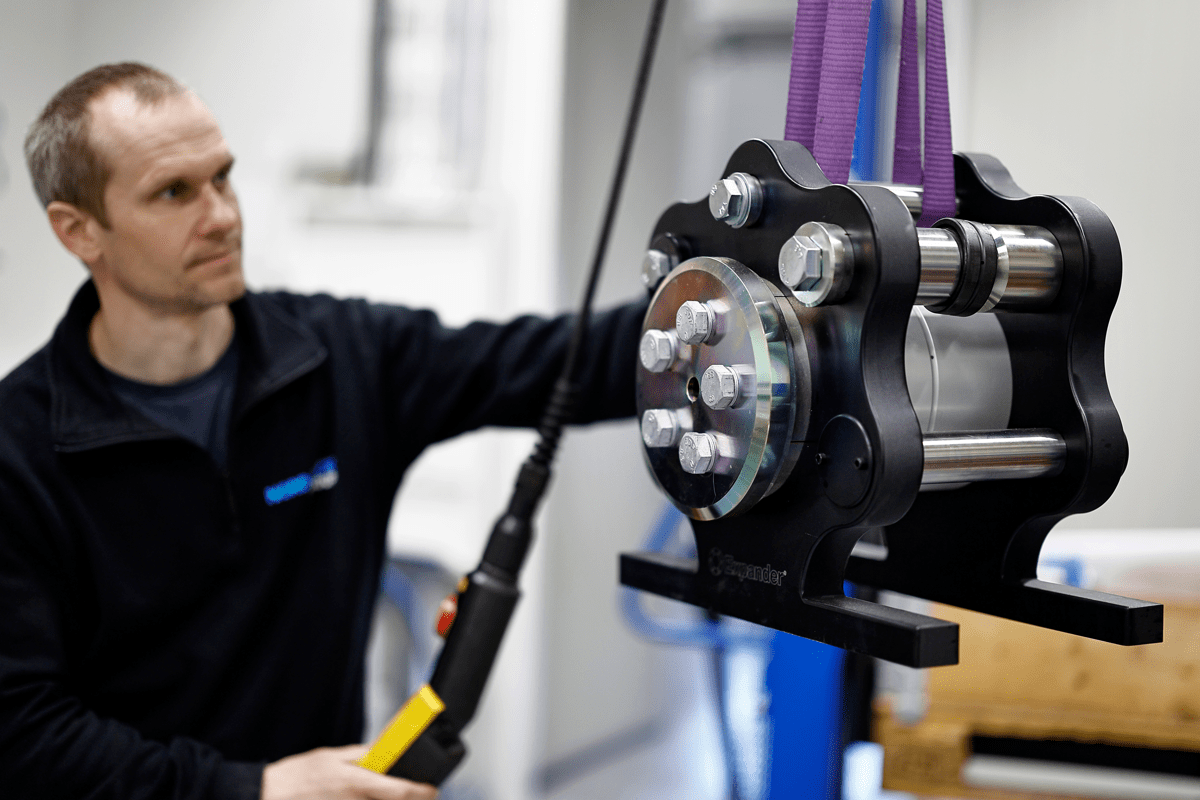

What do the Shinkansen high speed railway in Japan, Burj Khalifa in UAE, NASA space probes and offshore wind turbines have in common? They are prime examples of constructions with constant vibrations causing stress on the applications which, if not secured properly, jeopardizes safety. Most people don’t devote a thought to bolts loosening – but we do. Every minute. Every hour. All day. All Year. Our promise to build connections that last goes beyond manufacturing the best bolting technologies to expert support and pioneering digital solutions.

As a CNC Machinist, you will be machining component parts for mechanical tensioning tools in compliance with technical engineered drawings, operation sheets, specifications and written or verbal instructions, as well as established company policies and procedures. Measures machined parts to detect defects, adjust equipment and monitor tool wear during machine operation, as necessary. You are self-motivated and maintain a clean and safe work area. You will participate in both individual and company-wide continuous improvement activities and programs. Openly communicates opportunities for improvement to company employees and management, as appropriate. Monitors and documents issues, according to the company’s Quality Management System (QMS – ISO 9001:2015) to drive continuous improvement.

Our facility is located in Clinton, PA near the Pittsburgh Airport and relocation is not being offered for this position.

Your profile consists of the following areas of experience, knowledge, and responsibility:

- Adheres to safety programs and follows company safety policies and procedures, encouraging other employees to do the same.

- Reads and interprets instructions, procedures, and engineering drawings to machine products accurately and efficiently.

- Verifies work to be done by following appropriate dispatch lists and following job work orders.

- Uses basic measurement equipment such as calipers and thread gages to verify / inspect products for accuracy and uniformity during the machining processes.

- Performs machine set ups and operates machines.

- Confers with engineers, programmers, and production personnel to resolve machining concerns.

- Maintains precise manufacturing data in ERP, as needed.

- Understands and adheres to Quality Management System, properly documenting any issues.

- Manages, monitors, and maintains required tooling used in the manufacturing processes.

- Ensures a safe and clean work environment by keeping workspace clean and organized and performing daily machining cleaning / maintenance.

- Cross trains on multiple machines to increase machining knowledge and machining capabilities.

- Notifies Value Stream Manager of any equipment, material, or process issues and/or safety concerns and assists with maintaining of equipment.

- Maintains high quality standards for all machined products and reports scrap parts, as necessary.

- Investigates ways to minimize and/or eliminate duplication and non-value-added activities.

- Participates in Lean/5S initiatives by affecting changes in workspace.

- Follows all systems, policies, and procedures, as outline in the operating manual

- Organizes workflow to meet internal and external deadlines.

- Compiles, maintains, and files all required paperwork, records and documents, as directed.

- Manages correspondence efficiently and with good communication skills.

- Participates in training related to the company and/or job responsibilities.

- This list is not all inclusive and may include other duties as assigned and necessary for the operation and management of the business.

Requirements:

- High School Diploma or GED

- Minimum of 1 year of CNC machining experience or equivalent successful experience in a similar technical position

Eligibility Requirements:

- Willing and able to work 2nd shift.

- Willing and able to commute to work as scheduled.

- Willing and able to safely operate a fork truck and overhead cranes.

Desired Characteristics:

- Swiss lathe and milling experience are preferred

- Analytical ability

- Proficiency with reading and understanding technical drawings and documents.

- Ability to work under pressure with tight deadlines.

- Ability to demonstrate effective interpersonal skills, as well as sound judgement, professionalism, confidentiality, and good decision-making skills.

- Ability to effectively organize and prioritize a high volume of work.

- Ability to make the most effective use of one’s own time and that of others.

- Commitment and dedication to continuous improvement, including but not limited to continuous learning and training opportunities that support job responsibilities and personal growth.

- Ability to communicate effectively and professionally, both verbally and in writing.

- Ability to adapt and be flexible in a dynamic and collaborative environment.

- Demonstrate acute attention to detail and a high level of accountability.

We value diverse teams that work smarter and deliver solutions in a dynamic environment while offering challenging projects and opportunities to learn and develop for your success.

What we offer

- Opportunities to develop and grow professionally

- Genuinely great coworkers who want to see the company and each other succeed

- 401(k) with company match

- Health, vision, & dental insurance

- Life insurance

- Paid time off

- Company holidays

- Paid Parental leave

How to apply

Does this sound like the perfect opportunity for you? We’d love to hear from you!

Please apply with your CV and cover letter. Applications are reviewed on a rolling basis, so don’t wait!

Nord-Lock Group as an employer

Nord-Lock Group is a global leader in bolting and engineering solutions. From deep subsea to outer space, our promise to build connections that last goes beyond manufacturing the best bolting technologies. Our people are experts in the lifecycle of secure bolted joints, innovators at the forefront of digital solutions and committed to doing business with respect for people and planet. Our technology brands are all the original inventors

of their respective technologies: Nord-Lock® wedge-locking washers, Superbolt® mechanical tensioners, Boltight® hydraulic tensioners and Expander® System pivot pins. Nord-Lock Group is wholly owned by Investment AB Latour, an investment company quoted on the Nasdaq OMX Stockholm. The total turnover for Nord-Lock Group is 1.9 billion SEK and the company has more than 700 co-workers. For more information about us, please visit www.nord-lock.com.

- Department

- Superbolt & Boltight

- Role

- Blue Collar Pittsburgh

- Locations

- USA - Pittsburgh

USA - Pittsburgh

CNC Machinist - 2nd Shift

Loading application form